This was my Christmas present to myself.

It is a Schärf-Fix 2000 manual leather paring machine made by Teknomek HB in Sweden. I think the name means something like quick-sharp in German (presumably the model number ‘2000’ was chosen because it sounded futuristic when they were developing it!). It is used for easily and consistently thinning down leather in three different modes.

It is primarily intended for traditional bookbinders who cover books with leather, but it turns out that the construction of English-style concertina bellows has a lot in common with bookbinding. They are nicely designed and well-made machines but they are very expensive new, are highly sought-after by hobbyist bookbinders, and AFAIK no other manufacturers currently make a similar machine. I had to wait about a year for a second hand one to come up for sale on eBay. My backup plan had been to build my own by adding a roller and an adjustable blade holder to the frame of an old sewing machine.

The first operation mode is skiving. You turn the top knob to tilt the blade relative to the roller so that when you pull a piece of leather through it, it thins the edge of the piece to almost nothing at a shallow taper angle:

The reason for skiving edges is so you can glue one piece on top of another without a step, both for cosmetic reasons and so there isn’t an exposed edge to catch on things and come loose. This is what an overlapping joint might look like without any skiving:

And this is the same two pieces of leather but with the edges of both top and bottom pieces skived so the tapers match up. Looking at the vintage concertina bellows I have, joints made this way tend to be almost invisible. Unlike a butt joint, a skived overlap joint is air-tight and nearly as strong as the original leather:

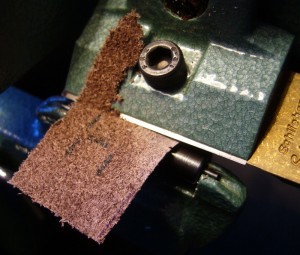

The machine’s second mode is splitting: if you set the blade parallel to the roller it will pare the leather down to a controlled thickness. Although it can only pare strips 30mm wide, it’s possible to do wider pieces using multiple passes. There are two main reasons to split leather: to make it more flexible, and to compensate for variations in thickness in different parts of a hide. This photo shows a piece I split down to the sort of thickness that I think is normally used in bellows construction:

The third mode of operation is probably not very useful for concertina making. You can replace the standard parallel roller with one that has a raised portion and set the blade parallel, so it cuts a furrow out of the middle of a piece of leather, forming a more flexible area. I think bookbinders use this technique at the hinges of a book.

Pingback: Tuning Bellows – Holden Concertinas