I have a set of press tools that can make metal button caps from sheet metal, in two common diameters: 4.7mm (3/16″) or 5.7mm. The advantage of buttons with metal caps over acetal/Delrin (plastic) cores is that they are much lighter weight than a solid button made from the same metal. Lighter buttons make the overall instrument noticeably lighter, and also make the action feel quicker by reducing inertia. I have made pressed metal caps from nickel silver or brass, and I have also nickel plated them. There is some variation possible in how rounded the tip of the button is according to player preference.

5.7mm diameter nickel silver capped buttons on No. 3:

4.7mm diameter nickel silver capped buttons on No. 4:

4.7mm diameter nickel plated brass capped buttons on No. 9. Note that some of them were textured like a golf ball to provide a slightly different tactile feel, to aid with locating your home position on the keyboard:

4.7mm brass capped buttons on No. 11, with a slightly more rounded tip profile:

The other way to make metal buttons is to turn them from solid bar. I have made buttons from solid nickel silver in the past, but the disadvantage of making solid buttons from a dense metal like NS/brass or stainless steel is that they can make the instrument feel quite heavy and slow down the action due to increased inertia. If you use a lighter metal like aluminium alloy, they are only slightly heavier than buttons capped with brass or nickel silver. An advantage of turning them from any solid material is the client has more freedom to pick whatever diameter and tip profile they want. No. 10 has solid aluminium 4.7mm buttons, to match its aluminium end plates:

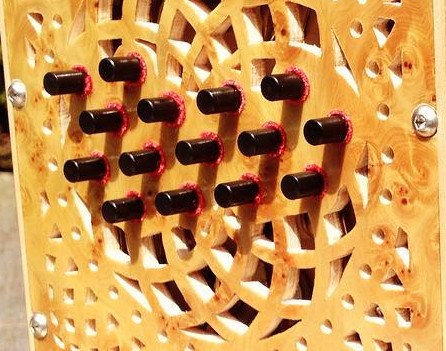

It is also possible to turn buttons from wood, as long as it is a very dense fine-grained wood like boxwood. Wooden buttons are probably the lightest weight option, and they feel relatively warm and pleasant to the touch and not too slippery. Because they are turned from solid, the client is free to choose their preferred diameter and tip profile. No. 8 has 5.7mm diameter boxwood buttons:

I’ve recently been gifted some antique lignum vitae bowling balls that I hope to make buttons from in the future.

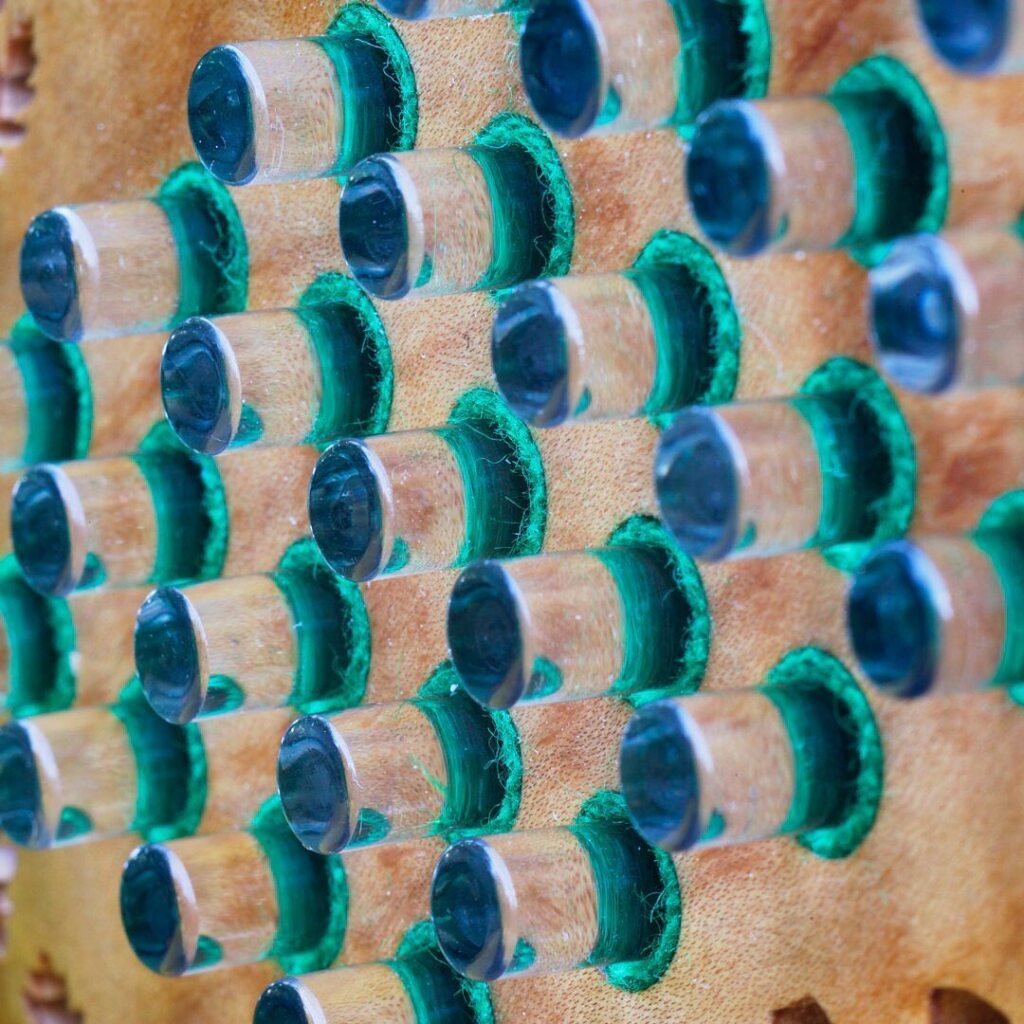

The fanciest type of button I have made is borosilicate glass. Because I don’t have a practical way to reduce the diameter of the glass rod I am limited to making them in a small selection of diameters, the most practical of which are 5mm or 6mm. No. 7 had 6mm diameter glass buttons. Note that the green tint comes not from the glass itself, which is totally clear, but from a combination of green dye and green bushing cloth.

I have also turned buttons from black acetal/Delrin, though it is my least favourite option. No. 1 has 4.7mm diameter black acetal buttons: